31 May 8 2: Direct Materials Cost Variance Business LibreTexts

This means that the actual direct materials used were less than the standard quantity of materials called for by the good output. We should allocate this $2,000 to wherever those direct materials are physically located. However, if $2,000 is an insignificant amount, the materiality guideline allows for the entire $2,000 to be deducted from the cost of goods sold on the income statement. The direct materials quantity variance should be investigated and used in a way that does not spoil the motivation of workers and supervisors at work place. Variances occur in most of the manufacturing processes and for almost all cost elements.

Direct Materials Quantity Variance: Definition

If the outcome is a favorable outcome, this means the actual costs related to materials are less than the expected (standard) costs. According to standards, the company was allowed to use an input of 35,574 tons to produce an output of 32,340 tons (the actual output). However, it used only 34,100 tons of materials which resulted in a favorable direct material yield variance. Direct material yield variance (also known as direct material usage variance) is the result of producing a quantity of output that is different from planned or standard quantity using a certain standard amount of input materials.

Example: How to Calculate Direct Materials Quantity Variance

This year, Band Book made 1,000 cases of books, so the company should have used 28,000 pounds of paper, the total standard quantity (1,000 cases x 28 pounds per case). However, the company purchased 30,000 pounds of paper (the actual quantity), unreimbursed employee expenses what can be deducted paying $9.90 per case (the actual price). The following equations summarize the calculations for direct materials cost variance. An unfavorable outcome means the actual costs related to materials were more than the expected (standard) costs.

Advanced Techniques in Variance Analysis

In addition to this decline in productivity, you also find that some of the denim is of such poor quality that it has to be discarded. Further, some of the finished aprons don’t pass the final inspection due to occasional defects not detected as the aprons were made. Whichever direction this takes, you may find your production department laying blame on the purchasing team for buying substandard product. Managers can better address this situation if they have a breakdown of the variances between quantity and price. Specifically, knowing the amount and direction of the difference for each can help them take targeted measures forimprovement. Beta Company processes three materials, namely, material A, material B, and material C, to produce its only product known as product K.

- If the actual price paid per unit of material is lower than the standard price per unit, the variance will be a favorable variance.

- Keep in mind that the standard cost is the cost allowed on the good output.

- Anyunexpected increase in steel prices will likely cause significantunfavorable materials price variances, which will lead to lowerprofits.

- Analyzing direct material variance is a powerful tool for businesses aiming to maintain cost control and enhance profitability.

In a multi-product company, the total quantity variance is divided over each of the products manufactured. Sharing variance reports and findings with relevant departments fosters a collaborative environment where everyone is aware of cost control objectives. For instance, procurement teams can work closely with suppliers to negotiate better prices, while production teams can implement process improvements to reduce material waste. This cross-functional collaboration ensures that all aspects of the business are aligned towards achieving cost efficiency. Effective management of direct material variance can lead to significant savings and better resource allocation. It also helps identify inefficiencies within the supply chain or production process that may otherwise go unnoticed.

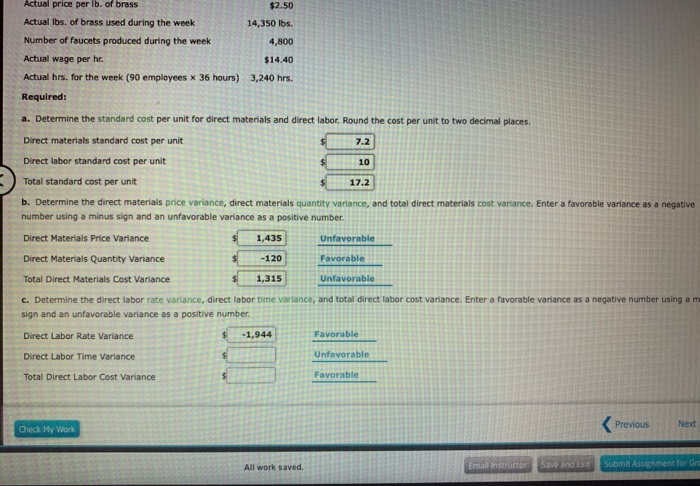

2 Compute and Evaluate Materials Variances

Actual and standard quantities and prices are given in the following table for direct materials to produce 1,000 units. Total actual and standard direct materials costs are calculated by multiplying quantity by price, and the results are shown in the last row of the first two columns. Analyzing direct material variance is a powerful tool for businesses aiming to maintain cost control and enhance profitability. By delving into the specifics of variances, companies can uncover inefficiencies and make informed decisions to optimize their operations. The first step in this analysis is to regularly review variance reports, which provide a snapshot of how actual costs compare to standard costs. These reports should be detailed and timely, allowing managers to quickly identify and address any discrepancies.

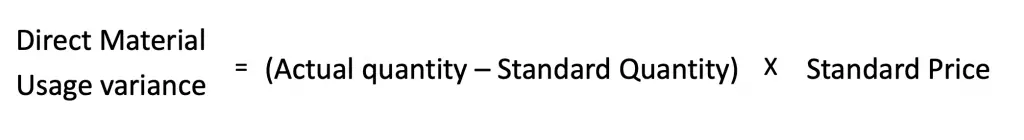

The net direct materials cost variance is still $1,320 (unfavorable), but this additional analysis shows how the quantity and price differences contributed to the overall variance. The total direct materials cost variance is also found by combining the direct materials price variance and the direct materials quantity variance. By showing the total materials variance as the sum of the two components, management can better analyze the two variances and enhance decision-making. In this case, the actual quantity of materials used is 0.20 pounds, the standard price per unit of materials is $7.00, and the standard quantity used is 0.25 pounds.

A favorable variance occurs when the cost to produce something is less than the budgeted cost. Favorable variances could be the result of increased efficiencies in manufacturing, cheaper material costs, or increased sales. For example, the unfavorable price variance at Jerry’sIce Cream might have been a result of purchasing high-qualitymaterials, which in turn led to less waste in production and afavorable quantity variance. This also might have a positive impacton direct labor, as less time will be spent dealing with materialswaste. Note that both approaches—the direct materials quantity variancecalculation and the alternative calculation—yield the sameresult. The standard quantity of 420,000 pounds is the quantity ofmaterials allowed given actual production.

The ultimate motive behind their calculation is to control costs and enhance improvement. Note that both approaches—the direct materials price variancecalculation and the alternative calculation—yield the sameresult. This setup explains the unfavorable total direct materials variance of $7,200 — the company gains $13,500 by paying less for direct materials, but loses $20,700 by using more direct materials.

¿Puedo ayudarle en algo?

¿Puedo ayudarle en algo?

No Comments